How We Built a Cellar Door: Why Soul Matters More Than Speed

Old House Season: The Ritual of Repair

Every fall, Sean makes his rounds — part ritual, part sport — inspecting every inch of Robins Hollow like a human energy audit. Drafty window? He marks it. Leaky faucet? Noted. Cellar door? Always the same verdict: “This has got to be next.”

He’s right, of course. The old cellar door had long since stopped doing its job. The wood was soft in spots, the paint cracked, and after every storm it seemed to welcome in as much water as it kept out.

Readers of Winter Is Coming: How We Prepare Our Nearly 200-Year-Old Home will recognize this theme — our quest to tighten the envelope, one creak, crack, and draft at a time. The cellar door had haunted that list for years.

This is a story about finally fixing it. But more than that, it’s about doing it beautifully — the kind of fix that feels as right for the soul as it does for the structure.

From Rot to Revelation

Sag Harbor hatch door inspiration

The cellar door we inherited wasn’t original, but it wasn’t far from failing. The wood had begun to delaminate, the hinges were sinking, and when it rained, the water treated it like an invitation.

If you own an old house, you know this feeling — that one nagging project that lets in the weather and the guilt.

We knew exactly what we wanted instead. Every year, we take a slow drive through Sag Harbor — top down in Chester’s when the weather cooperates — and wander through a favorite design showroom tucked behind a green Dutch door. The showroom’s back patio is a dream: a brick basketweave courtyard, a weathered cedar table, and, just beyond, a cellar hatch so solid and graceful it seemed like sculpture.

Every visit, we lingered there. Every time, I’d say, “That’s the door I want.”

Sean, in this case ever the pragmatist, countered with his go-to: “A Bilco door is airtight and installed in a weekend.”

He wasn’t wrong. But metal doors don’t make your heart skip. They don’t feel like they belong to a house that’s stood for nearly two centuries. The house deserved better — a door that would last, but more importantly, one that would belong.

Building the Cellar Door (in the Dining Room)

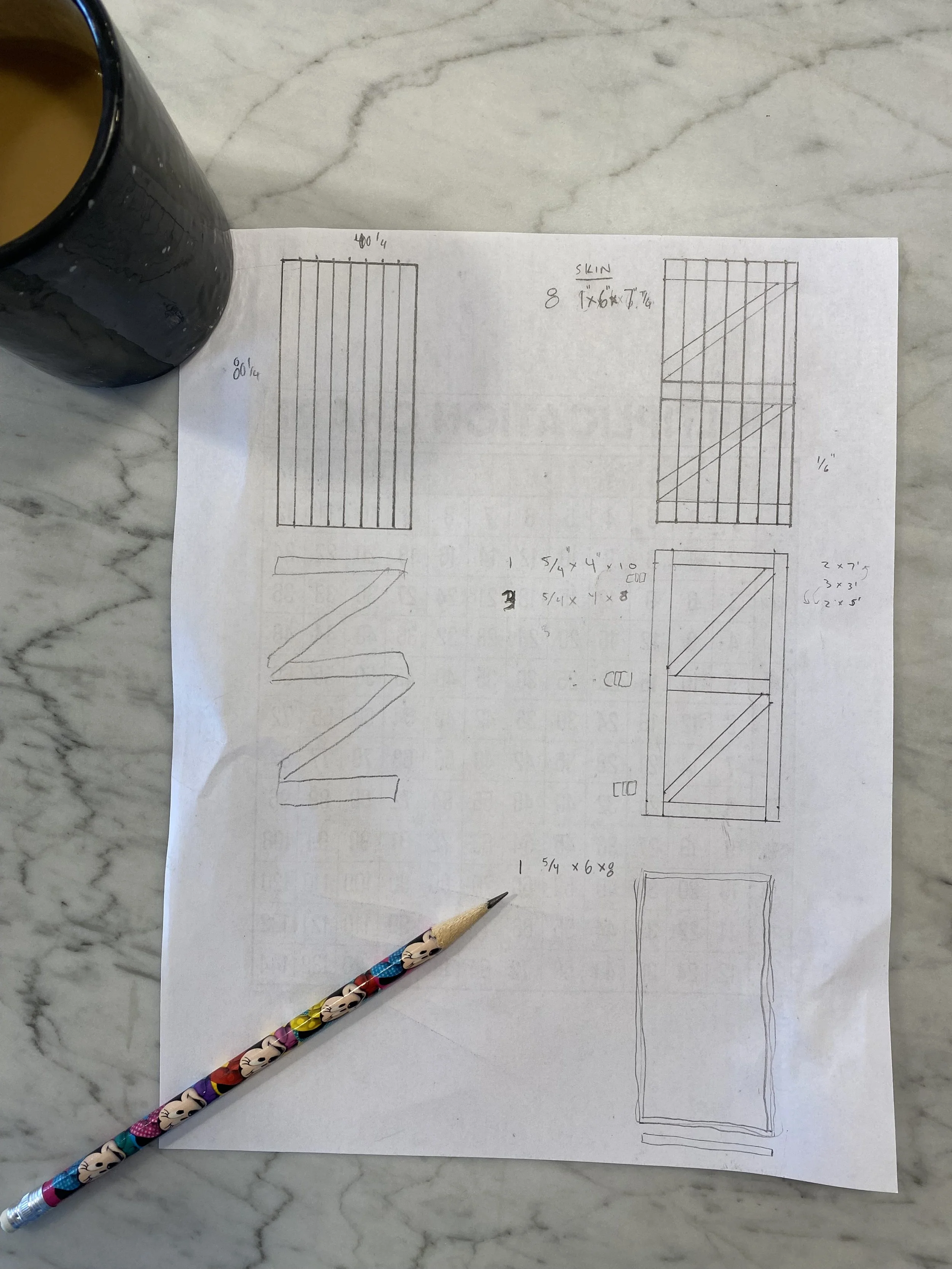

As with most of our projects, we began optimistically — sketches spread across the table, budget scribbled on a Post-it, a timeline that suggested “two weeks, tops.” (We should have known better. It took three months, which, in Robins Hollow time, is basically on schedule.)

The dining room, as usual, became our workshop. Sawhorses replaced chairs. Coffee cups mingled with clamps. Dinner happened around piles of lumber.

We measured, cut, and dry-fitted each board for the angled hatch panels. This was our first time using West System Epoxy — a slow-curing resin that bonds like iron but works like honey. We learned how to meter and mix it with precision — a quiet race against the clock to spread the epoxy before it seized, each pour its own small test of timing and teamwork.

Each piece of mahogany came together slowly, glued and clamped until it held like one solid sheet. We didn’t paint it — just sealed it with tung oil, eventually. It took several false starts and a stretch of uncooperative weather before we caught the right window to finish.

By the time the panels were ready, we’d gotten pretty good at it — just in time to be done. That’s become a running joke in our house: by the time we master a new technique, it’s always the end of the project.

Still, the process never gets old. There’s a rhythm to working side by side — the unspoken communication, the small debates, the moment when something fits just right and you both know it.

The Moment It Fit (and Why It Still Does)

Installation day arrived cold and bright — the kind of day that makes your breath visible and your coffee essential. The last hinge swung into place, the door lowered smoothly, and when it shut, it did so with that deep, satisfying thud we’d been chasing for months. For a moment, it felt perfect.

Then came the rain.

We hadn’t yet sealed it, so we covered the new mahogany door with a blue tarp, weighted by bricks, waiting for the weather to cooperate. Days turned into weeks. By the time the sky finally cleared, the wood had taken on a slight curve — just enough to remind us who’s really in charge: the elements.

The door is solid mahogany, which means it’s beautiful — and heavy. That small warp meant the snug fit we’d planned now needed a little help. A line of weatherstripping took over the job the wood was meant to do, closing the gap and keeping the wind where it belongs.

It wasn’t the flawless finish we’d imagined, but in its way, it’s better — a slight warp that will forever be part of its personality.

But what a presence it has. Friends and neighbors mention it constantly. It’s one of those details that draws people in, that quietly says, “Someone loved this into being.”

Sealing the door with tung oil once the rain stopped and the weather warmed

Why We Build Instead of Buy

There’s no shortage of faster or cheaper ways to do what we did. But building this door reminded us why we DIY in the first place.

A good door keeps out the cold. A great door keeps in the story. It’s not about saving money — it’s about adding meaning. Every handmade piece, every slightly imperfect joint, connects us more deeply to this house and its history. It becomes part of its DNA.

That’s the heart of stewardship: adding your layer to a house that will outlast you.

If you haven’t already, you can revisit our related posts:

→ Winter Is Coming: How We Prepare Our Nearly 200-Year-Old Home for the Season

→ Don’t Let a Cheap, Ill-Fitting Door Ruin Your Historic Home

How to Build (or Commission) a Door with Soul

Our custom, heritage cellar door

If you’re ready to take on a project like this, here’s how to start:

DIY Builders: Download our full Cellar Door Plans in this week’s newsletter — the same blueprint we used to build ours.

Collaborators: Bring the plans to a trusted carpenter who understands traditional joinery and weatherproofing.

Dreamers: Start smaller. A new latch, a handcrafted trim piece, or simply sealing your woodwork properly — it all counts.

A few quick tips we learned:

• Seal wood on all sides before install (or risk the warp we did).

• Dry-fit everything before gluing.

• Use materials that will age gracefully — mahogany or cedar.

Legacy isn’t built in a day. It’s built one nail, one hinge, one season at a time.

Your Turn: What Would You Build?

What’s one project you’ve done — or dream of doing — that makes your house feel more yours? Tell us in the comments.

Because at the end of the day, every great old house needs care, courage, and one beautiful door that says: we’re still building the story.